Get in touch

Phone: 812-386-6015

Email: matt@rpmtool.com

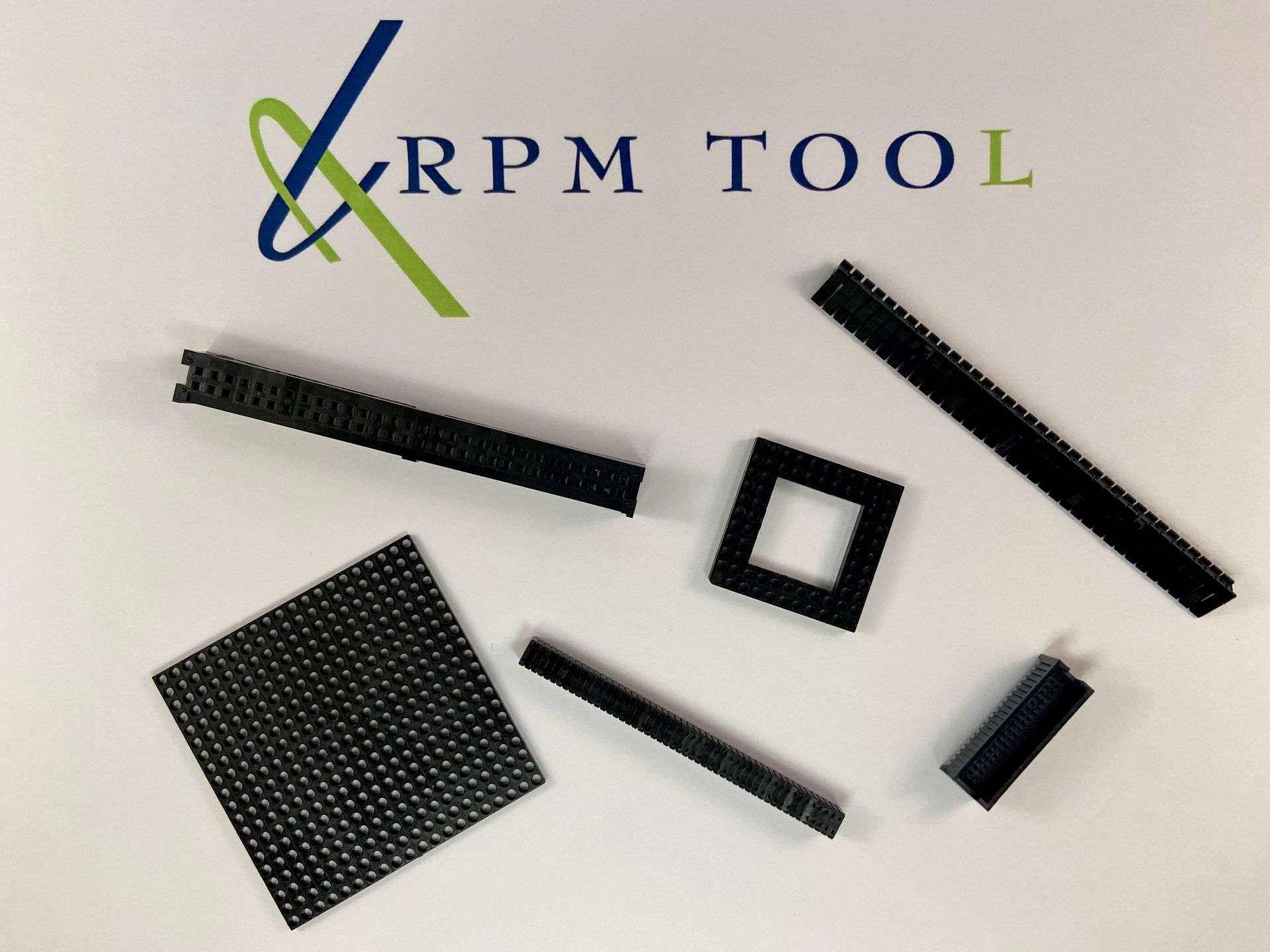

Injection Molding

Advanced Injection Molding Solutions

Over 35 years in running a variety of material including engineered grades.

- 18 injection mold press machines

- 40 to 610 ton

- Horizontal and up to 90 ton vertical

- 30 grams to 1,729 grams

- Resistance welding

- Light assembly

- 21,600 square feet of production area

All dies and molds are maintained regularly by our full-service Tool Room who are readily available for any tooling repairs and changeovers to ensure quality parts are being produced. With the aid of computer aided design (CAD) software, we meticulously develop molds and tooling that are tailored to your specifications, ensuring precise replication of every detail.

Key Features of Injection Molding

Injection Molding stands out for its versatility and design freedom, cost-effectiveness and efficiency, as well as its exceptional precision and quality.

Design Freedom

Enables the creation of complex shapes, intricate details, and precise geometries that may be challenging or impossible to achieve with other manufacturing processes.

Cost-Effectiveness

Allows for high-volume production with minimal labor requirements. The ability to rapidly produce large quantities of identical parts reduces per-unit costs and enhances overall manufacturing efficiency.

Exceptional Precision

Consistent quality in the production of plastic components. Advanced injection molding machines with precise temperature and pressure control ensure accurate replication of the mold's intricate details.

Talk With Our Team Today!

Collaboration and partnership are fundamental to our approach. We value the trust our clients place in us, and we work closely with you throughout the entire process. Our experienced team is always available to provide expert advice, offer design optimizations, and address any concerns or queries you may have. We believe in building long-lasting relationships based on trust, reliability, and exceptional service.

Choose RPM Tool for your Injection Molding needs and unlock the full potential of plastic component manufacturing. Experience the difference that advanced technology, precision, and unmatched quality can make. Contact us today to discuss your project requirements, and let us drive your success through our Injection Molding expertise.